咸宁市洪盛模具科技有限公司

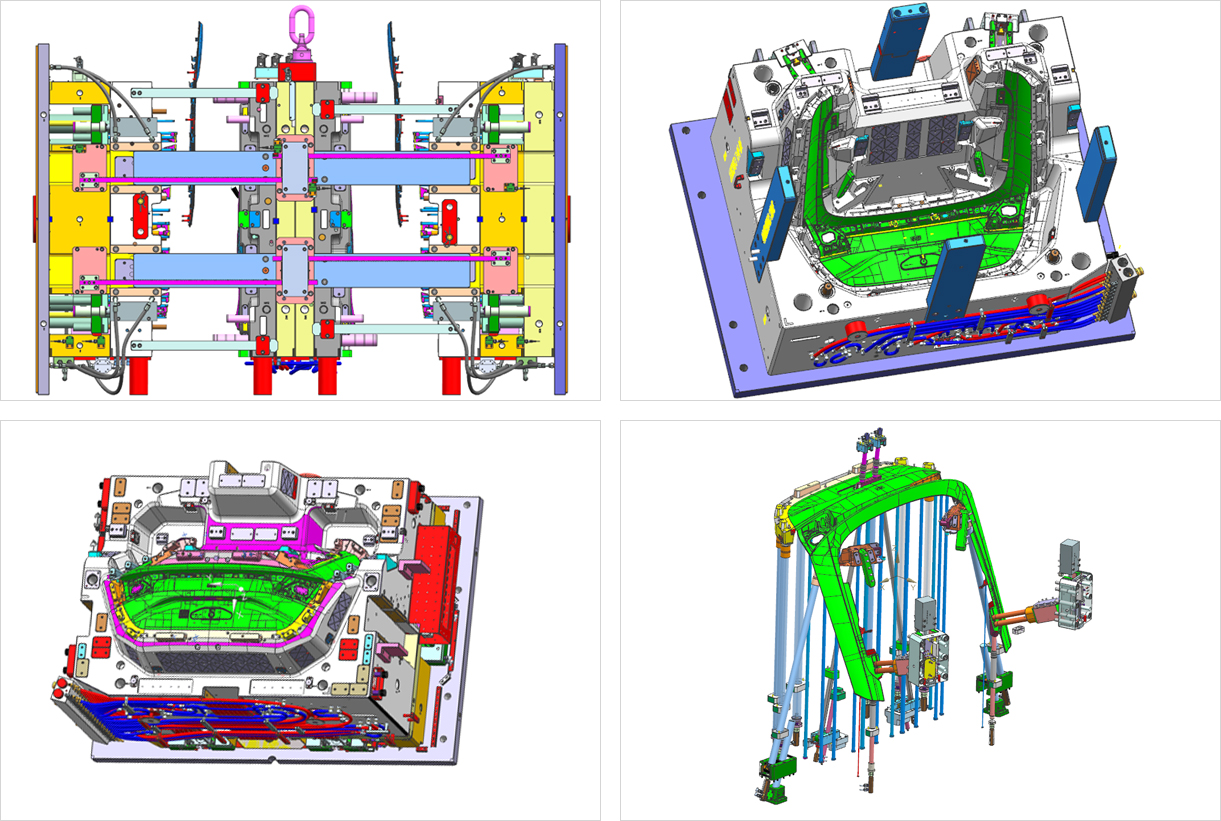

Mold Design

- Categories:Mold manufacturing

- Time of issue:2021-07-19 10:58:06

- Views:0

Mold design capability plays a key role on every project. We have a team of 52 experienced designers among whom there are about 15 designers with mold design experience above 15 years, 30 employees with 10 years mold design experience. We utilize the state-of-the-art design software and the secondary development design software of our own intellectual property rights. We have set up our own database of standards parts and get it constantly optimized to improve efficiency, decrease error rate, and dramatically reduce design lead time.

Mold design capability plays a key role on every project. We have a team of 52 experienced designers among whom there are about 15 designers with mold design experience above 15 years, 30 employees with 10 years mold design experience. We utilize the state-of-the-art design software and the secondary development design software of our own intellectual property rights. We have set up our own database of standards parts and get it constantly optimized to improve efficiency, decrease error rate, and dramatically reduce design lead time.

Prior to the official tool kick off, our designers and project engineers will launch an internal meeting to study and analyze the potential issues regarding gate locations, wall thickness, part warpage, shrinkage, etc., and come up with different proposals and solutions for the open issues. With the study result, we'll suggest customer selecting out the preferred structural design proposal. Once the proposal is confirmed, we will make mold flow analysis for each part with emphasis on part filling, welding line, cooling and warpage. Then our designers will summarize a feasibility report (DFM) and a mold flow report to customer. When we finish deep discussion with customer and getting preliminary confirmation, we will take the best mold structure design solution for the 2D and 3D mold design. And our designers will work with production staff to review the manufacturability of the designed mold. According to the review result, mold design will be updated and handed over to design manager for review. After that, the optimized mold design will be submitted to customer for final approval.

Adhering to the design philosophy of "profession, high efficiency, timely reply and good control of the manufacturing cost".

We're always committed to providing satisfactory design and service to our customers, which is the mission that LeadMould design team works for.

Copyright © Hongsheng(Xianning)Mold Technology Co.,Ltd. 鄂ICP备16009333号

Copyright © Hongsheng(Xianning)Mold Technology Co.,Ltd.